Taco Bell: When the trendy fast food meets the top of the game.

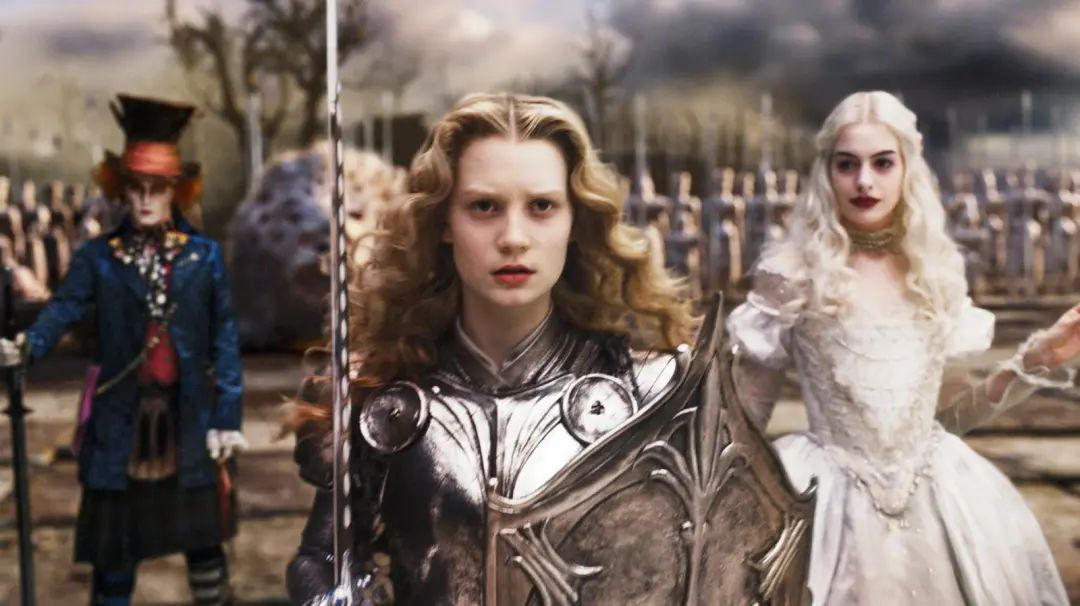

One is the trendy fast food, and the other is the top of the game. What kind of chemical reaction will happen when the hot American Mexican Tower meets Valkyria who is fighting for beauty?

In this hot July, Taco Bell, a famous American Mexican fast food brand, joined hands with Crash 3 to launch a summer joint activity of "Hot Taco, Delicious Crash" nationwide. In order to allow consumers to experience the atmosphere of the game in an immersive way, Taco Bell not only provides exclusive catering, joint packaging and package around the super-high-standard carnival for all the captains, but also launches 20 restaurants with the theme of Collapse 3 all over the country, from window stickers to table stickers, and the counter layout all reflects the elements of various games. The four leading characters at the door are eye-catching and the fans have taken photos and punched in.

At the same time, Taco Bell also issued a professional training manual specifically for restaurant partners, requiring restaurant employees to understand games and joint roles, customizing various "secret codes" for captains and providing rich gifts to make customers feel full of atmosphere, while enjoying food, experience links and fetters that have never existed in the virtual world.

"Iron Powder Shop Assistant" met "Captain Customer"

"Are you my captain?" A Zhi, an employee of Guangzhou Tianhe Vanke Taco Bell’s "Collapse 3" theme restaurant, warmly greets customers with the mantra of the game character Raiden Mei.

A Zhi is a big fan of the game "Crash", and he has liked it for 7 years since the game was launched. "I am really excited when I know that Taco Bell and Collapse 3 are linked! I didn’t expect to be able to play my hobbies at work and bring customers an immersive experience of’ food+games’. It can not only recommend delicious food for gamers, but also let restaurant partners know my favorite collapse 3. " In addition to participating in the layout of the theme restaurant, A Zhi naturally became the "teacher" of other partners in the restaurant. According to the training manual, A Zhi took other partners in the restaurant to play games, experience games and understand games.

"Please, another me." After the theme restaurant was launched, in Guangzhou Tianhe Vanke Taco Bell, there were signs of linkage one after another. With the help of A Zhi, other partners in the restaurant knew a lot about the roles of Collapse 3. When gamers communicated with Coser, everyone could accurately say the names of the roles described by the players and actively interact with consumers.

On the first day of the activity, Mike, a gamer, came to Taco Bell. At the suggestion of A Zhi, he selected Taco Bell, which suits his taste, and took photos and punched in every corner of the theme restaurant with Taco Bell and his favorite game surroundings. "I’m so happy. Taco Bell theme restaurant is really like a game venue in another space. Both players and restaurant employees are highly involved. Here, I found a strong sense of belonging."

Considering the hot weather in Guangzhou during the event, in order to let enthusiastic consumers enjoy better service, restaurants in A Zhi also opened their doors in advance during the event, so that customers waiting in line outside could wait in the restaurant. The restaurant will also provide customers with a second paper bag and taco cover at the request of customers when conditions permit, which is convenient for them to collect, and the strength is "pet powder".

Power generation for love Coser beautiful girl realizes her dream

The "magic girl facing the DPRK" started playing Collapse 3 a year and a half ago. She is usually taciturn, but she talks about Collapse 3 endlessly. Chao Chaochao said that in the game, she experienced the wonderful friendship between girls, and she also quoted Alicia, the character in the game, to explain why she participated in this activity.

"only spend time on people you like, but everyone likes it; I only pay attention to interesting things, but everything is interesting. For me, food and games are interesting things. "

On the first day of the event, Chao Chao wore her favorite "Keren" uniform and came to Taco Bell’s "Collapse 3" themed restaurant in Wuhan Guojin Tiandi. As a "house girl", she not only tried Taco for the first time, but also met a group of like-minded "captains", which made her praise the brand again and again.

"The first time I ate Taco Bell, I fell in love with Taco Cake. The cheese inside tasted good, and I also liked the whole restaurant style. Now I have become a fan of Taco Bell. In the future, I will often meet my friends in Taco Bell to talk about our favorite games and food. " The DPRK said.

After the DPRK told the DPRK that she knew about Taco Bell’s activity, she and her friends were very excited. They rushed to make their favorite character Keren’s costume overnight, hoping to show it to like-minded friends in the restaurant.

"It’s so lively offline. Usually in life, it’s hard for me to meet partners who discuss the crash game together. As a Coser, there are few opportunities for us to take photos with the characters. This activity not only made me gain so many friends at once, but also fulfilled our Coser’s dream. Taco Bell’s friends were so enthusiastic and helped us take many beautiful photos. "

For their favorite game Collapse 3, "Magic Girl Facing the DPRK" also wants to call the official: Can you give Keren Kaslanna a birthday?

From "social fear" to "social cow", he gained online and offline friendship.

In the early morning of July 8, at the entrance of Taco Bell in Shanghai Seven Babies Dragon City, a penny classmate from Shanghai Songjiang University Town came to the queue early, and he was the first in the queue, hoping to get the linked peripheral products as early as possible. Xiao Qian originally planned to go back to his hometown for an internship in the summer vacation, but just a few days ago, he learned that the joint activity of Taco Bell and Crash 3 would land in Shanghai. In order to participate in offline activities and collect their favorite game surroundings for his good friends, he did not hesitate to sign the high-speed train home.

It’s still early to open the restaurant, so Penny sat on the ground, put on headphones and played games with his iPad. Just as he was absorbed in the game world, he suddenly felt someone patted him on the shoulder. He turned his head and found a boy behind him, shyly showing him his mobile phone. It turned out that they had the same game role, from role to play, from seiyuu to lines. Penny and this newly met "stranger" soon became familiar.

During the conversation, Xiao Qian learned that the boy who greeted him on his own initiative was Xiao Gong, a native of Shanghai. Xiao Gong is usually a little introverted and not used to dealing with strangers. A few days ago, he happened to see the information of joint activities in the player community, thinking that other game lovers should gather in the offline theme store, so he came to the store early in the morning and wanted to make like-minded friends while getting around the game. At the event site, I saw Xiao Qian, who has a common role in the game, and the idea of wanting to talk to people about the role of the game defeated the "social fear". Xiao Gong took the courage to take the initiative to talk to Xiao Qian and gained an offline friendship.

"This kind of off-line gathering is really interesting," Xiao Gong said. "I tasted new food and made new friends. It was so happy for us to discuss the role experience together. I hope there will be more such activities in the future. "

In Taco Bell’s "Collapse 3" theme restaurant in 11 cities, every player and consumer has gained their own fun and resonance here. Some have made new friends, some have sought happiness in cosplay, and some have traveled thousands of miles to another city just to collect the surrounding of their beloved characters … Because of their love and food, these young people gathered in Taco Bell’s restaurant, turning virtual adventures into real links, and also making them fully feel the brand.

With the increasing demand of young consumers for consumption experience, restaurants are no longer just places for dining, but have become "self-projection" of young consumers for a better life. From the official announcement that James LeBron became the spokesperson to the recent co-signing of Collapse 3, Taco Bell has always grasped the trend of young consumers, providing consumers with hot and energetic international popular American Mexican fast food, and at the same time leading the trend culture with a vibrant image.

[advertisement]

(Disclaimer: This article is reproduced and published for the purpose of spreading commercial information on this website, and does not represent the views and positions of this website. All rights and legal responsibilities of the texts, drawings, audio and video materials involved in this article belong to the material provider. This website does not make any guarantee or commitment to the authenticity of all the information such as words and pictures, nor does it constitute any suggestions for purchase or investment, so the operator bears his own risks. )